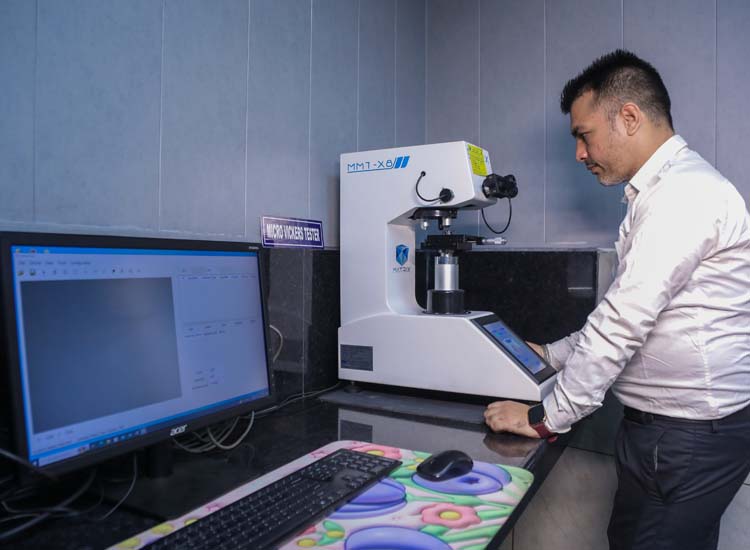

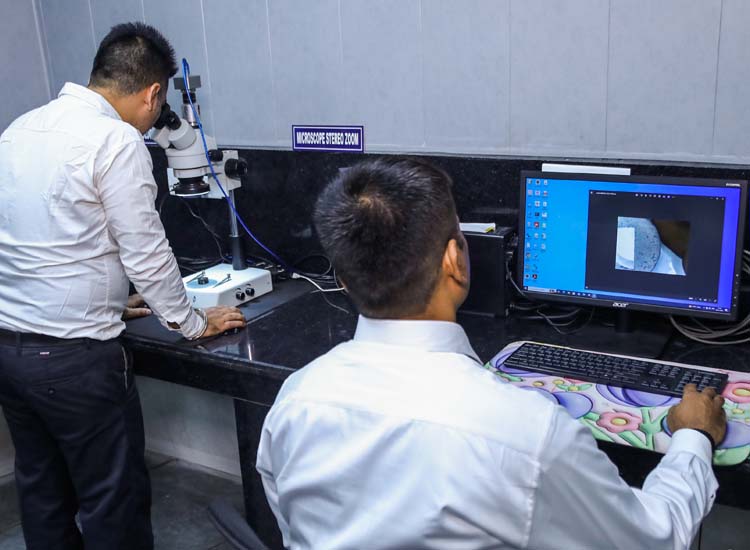

Our advanced testing and inspection processes rely on cutting-edge equipment to ensure precision, durability, and compliance with international quality standards.

- Rockwell Hardness Tester

- Brinell Hardness Tester

- Microscope Stereo Zoom

- Microscope Metrology

- Infrared Therometer

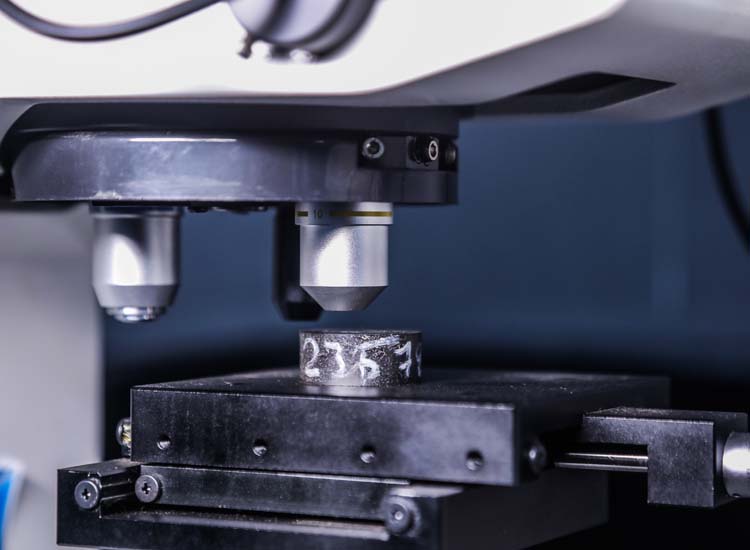

- Micro Vickers Hardness Tester

- Roughness Tester Machine

- Universal Test Machine

- Magna Flux Machine

- Digital Hardness Tester

- Polishing Machine

- Mold Making Machine

- Abrasive Cutting Machine